Introducción

En el campo del corte por láser, la búsqueda de una mayor eficiencia, mejor calidad y menor costo nunca se detiene. En el pasado, nos centramos en aumentar la potencia del láser y la velocidad de corte. Sin embargo, muchas empresas encuentran que incluso con las máquinas de corte más rápidas, todavía enfrentan puntos problemáticos persistentes: dificultad para aprovechar los materiales remanentes, pérdida de control durante el proceso de corte y la necesidad de un extenso pulido manual antes de la soldadura.

Estos problemas no pueden ser resueltos por un solo equipo; requieren una solución sistemática que cubra todo el proceso desde "pre-posicionamiento - monitoreo en proceso - post-acabado"Hoy, profundizaremos en cómo el sistema inteligente de circuito cerrado, compuesto por el dispositivo de bisel secundario, el sistema "Ojo Celestial" de BOCHU y el escáner de contorno BCW400F-E, inicia una revolución de eficiencia en el corte láser.

Limitaciones de las Soluciones Tradicionales de Bisel Secundario

Antes de la llegada de las soluciones de bisel secundario láser, la industria dependía principalmente de los siguientes métodos:

1. Biselado de Llama Semiautomático (Comúnmente conocido como "Tortuguita")

Ventajas: Estructura simple, bajo costo, fácil de usar.

Desventajas: Depende del marcado manual para posicionamiento, baja precisión, velocidad lenta, calidad de corte inestable en arcos y esquinas, completamente dependiente de la experiencia del operador.

2. Estación de Trabajo Robótica

Ventajas: Posee un cierto grado de automatización y capacidad de procesamiento flexible.

Desventajas: Área de procesamiento limitada (aprox. 1.5m×1.5m) debido al alcance del brazo robótico; basado en llama o plasma, la precisión de corte es pobre (>2mm) y la velocidad es lenta; la planificación de trayectorias para gráficos complejos tiene un umbral alto, y los costos operativos son elevados con fuerte dependencia del material.

El problema central es: Las soluciones tradicionales carecen de mecanismos efectivos de posicionamiento y compensación de deformaciones. Cuando ocurre una desviación, es necesaria la intervención manual, lo que dificulta garantizar la consistencia y eficiencia del procesamiento.

El Empoderamiento Preciso en la Etapa Temprana por el Escáner y el Ojo Celestial

Antes de que el bisel secundario pueda desempeñar su papel, el trabajo preparatorio es crucial. Esto depende de dos "vanguardias".

1. Escáner de Contorno BCW400F-E: De "Corte a Ciegas" a "Visible", Maximizando el Valor del Material

Función Principal: Es un sensor de visión basado en tecnología de láser lineal, diseñado específicamente para sistemas de corte. Su misión principal es reemplazar el ojo humano y los calibradores, realizando escaneo de alta velocidad sin contacto de placas (especialmente remanentes irregulares) para obtener datos de alta precisión sobre contorno, posiciones de agujeros, marcas, etc., con una precisión de hasta 0.005mm.

Valor de la Aplicación:

- Renacimiento de Remanentes: Frente a remanentes irregulares, la programación tradicional es impotente. El escáner puede obtener rápidamente su contorno digital, y el software realiza un anidamiento inteligente para ajustar nuevas piezas dentro de él. Posteriormente, el la función de bisel secundario puede seguir con precisión la trayectoria generada por el escaneo para realizar un procesamiento de alta calidad en estas piezas reutilizadas, maximizando su valor y ahorrando material al máximo.

- Alineación Precisa: Para piezas que requieren acabado secundario (como biselado) basado en orificios o marcas existentes, el escáner puede identificar automáticamente las características de referencia y calibrar la trayectoria de corte, asegurando la coaxialidad y transición suave del bisel con la estructura original, con errores controlables dentro de 0.02mm.

2. Sistema Sky Eye (Kit Inteligente de Restos): La "Primera Red de Seguridad" del Proceso

Función Central: Sky Eye es una solución de visión de alta gama que integra cámaras industriales, lentes ópticos y algoritmos inteligentes. Realiza un escaneo rápido y posicionamiento aproximado de las piezas formadas por corte recto antes del procesamiento secundario.

Valor de Aplicación: Antes de comenzar el biselado secundario, se confirma si la posición de la pieza coincide con la programación teórica. Esto evita desperdicios graves como biselar el borde incorrecto o abrir el bisel en la posición equivocada debido al movimiento de la placa o desviaciones del proceso anterior, proporcionando una garantía crucial de precisión inicial para el proceso de acabado de alto valor.

El Arte del Mecanizado de Precisión con Bisel Secundario

1. La Esencia del Bisel Secundario

El bisel secundario no es simplemente un corte repetitivo, sino un proceso independiente de acabado. Realiza un mecanizado fino tridimensional en el borde después del primer corte controlando con precisión el ángulo, potencia, velocidad y presión de gas del cabezal de corte.

2. Tres Valores Fundamentales

Valor Uno: Corrección de Defectos, Logrando Bordes Perfectos

Detalles Técnicos: El primer corte en placas gruesas produce fácilmente escoria, rebabas y desviación de perpendicularidad (conicidad). El bisel secundario emplea una estrategia de baja potencia, alta velocidad y escaneo de múltiples pasadas para "micro-tallar" el borde, reduciendo efectivamente la rugosidad del borde (valor Ra) de >12.5μm a 1.6-3.2μm, mientras corrige la conicidad para obtener una superficie de corte uniformemente vertical.

Escenario de Aplicación: Cumple directamente con los estrictos requisitos de calidad de borde en piezas mecánicas de precisión, bloques de válvulas hidráulicas, instrumentos de alta gama, etc., eliminando procesos posteriores como fresado y rectificado.

Valor Dos: La Solución Definitiva para el Pretratamiento de Soldadura

Detalles Técnicos: Puede programar y mecanizar ranuras en V, ranuras en U, ranuras dobles en J, etc., en cualquier ángulo según los requisitos del proceso de soldadura, con un error de ángulo controlable dentro de ±0.5°, y altura de cara raíz controlable. Esto proporciona una interfaz extremadamente consistente para la soldadura.

Escenario de Aplicación: Aplicable a todos los campos que requieren soldadura de alta calidad, como maquinaria de construcción, recipientes a presión y tránsito ferroviario. Los biseles limpios pueden reducir las brechas de soldadura, mejorar la consistencia de la penetración, eliminar fundamentalmente peligros ocultos como la falta de fusión y la penetración incompleta, y mejorar significativamente la resistencia estructural y el rendimiento de seguridad.

Valor tres: Superando el "desafío final" del corte de placas gruesas

Detalles técnicos: Para abordar el problema donde el primer corte en placas de más de 20mm puede no cortar completamente en la parte inferior ("corte incompleto"), el bisel secundario puede realizar cortes de desbaste inverso, usando parámetros especializados para eliminar con precisión los puntos de conexión inferiores, asegurando la separación completa y evitando la deformación térmica de la placa causada por la entrada excesiva de energía en un solo paso.

Monitoreo en tiempo real y corrección de errores en ciclo cerrado por el sistema Ojo del cielo

La incertidumbre durante el procesamiento es otro gran enemigo de la calidad. El sistema Ojo del cielo actúa como "guardián" en la etapa media del proceso.

Monitoreo de calidad en tiempo real: Durante el proceso de biselado secundario, el sistema Ojo del cielo monitorea continuamente el área de corte. Puede identificar inteligentemente situaciones anormales como "ruptura del haz", "obstrucción de la boquilla" y "contaminación de la lente de enfoque", deteniendo inmediatamente la máquina y emitiendo una alarma para evitar desperdicio en lote y proteger el costoso cabezal de corte biselado.

Compensación Dinámica de Errores: Las placas pueden desplazarse durante el procesamiento debido a "aflojamiento del dispositivo" o "deformación térmica", causando desviación entre la trayectoria real y la trayectoria teórica. El sistema Sky Eye puede comparar ambas en tiempo real, calcular automáticamente el valor de desviación (ejes X/Y/Z), retroalimentarlo al sistema de control para ajustar dinámicamente la posición de la cabeza de corte, logrando una compensación en bucle cerrado en tiempo real y asegurando que la tolerancia dimensional final de la pieza se mantenga estable dentro de ±0.03mm. Esto es crucial para procesar piezas grandes de varios metros de longitud.

Almacenamiento de datos y trazabilidad: El sistema puede almacenar automáticamente imágenes de corte, parámetros (potencia, velocidad) y datos de desviación para cada lote de piezas, formando un "registro de procesamiento". Si se detectan defectos posteriormente, se pueden revisar los datos para localizar el problema (por ejemplo, una desviación en un lote originada por deformación térmica de la placa), facilitando la optimización del proceso y cumpliendo con los requisitos de "trazabilidad completa del proceso" en industrias como la aeroespacial y dispositivos médicos.

El ciclo cerrado de producción inteligente: 1+1+1 > 3

La combinación de los tres no solo acumula funciones, sino que constituye un ciclo cerrado de producción altamente inteligente:

- Etapa inicial (Escáner): "Escaneo y posicionamiento" – Resuelve el problema de "¿Dónde está el material?", proporcionando un datum de mecanizado preciso para el biselado secundario y maximizando la utilización del material.

- Etapa media (Ojo del cielo): "Monitoreo y corrección" – Resuelve el problema de "¿Es estable el proceso?", asegurando la fiabilidad del proceso de biselado secundario y la calidad constante.

- Etapa avanzada (Bisel secundario): "Mecanizado de precisión" – Resuelve el problema de "¿Es aceptable el borde?", produciendo finalmente piezas de trabajo perfectas, listas para usar y de alto valor.

Beneficio Final: Este sistema puede reducir significativamente la tasa de desperdicio del 5% a menos del 1%, aumentar la capacidad de producción por lote en un 20%-30%, y eliminar completamente el proceso de rectificado antes de la soldadura, logrando un acabado verdaderamente "sin intervención humana".

Video y muestra:

Las Ventajas Adicionales de la Solución de Biselado Secundario de BOCHU

La solución de biselado secundario de BOCHU no es un simple reemplazo de los procesos tradicionales, sino una mejora integral en utilización de material, ajuste de proceso, capacidad de procesamiento, velocidad y precisión, costo y flexibilidad.

1. Mayor Ahorro de Material

Desventaja del Biselado de Un Solo Paso: Al biselar directamente sobre una placa completa, se debe reservar espacio entre las piezas para la trayectoria del corte del bisel, lo que resulta en un desperdicio significativo de placa.

Mejora con Bisel Secundario: Primero, realizar un corte recto inicial para el desbaste, permitiendo que las piezas se corten con borde común al máximo. Luego, realizar el acabado del bisel.

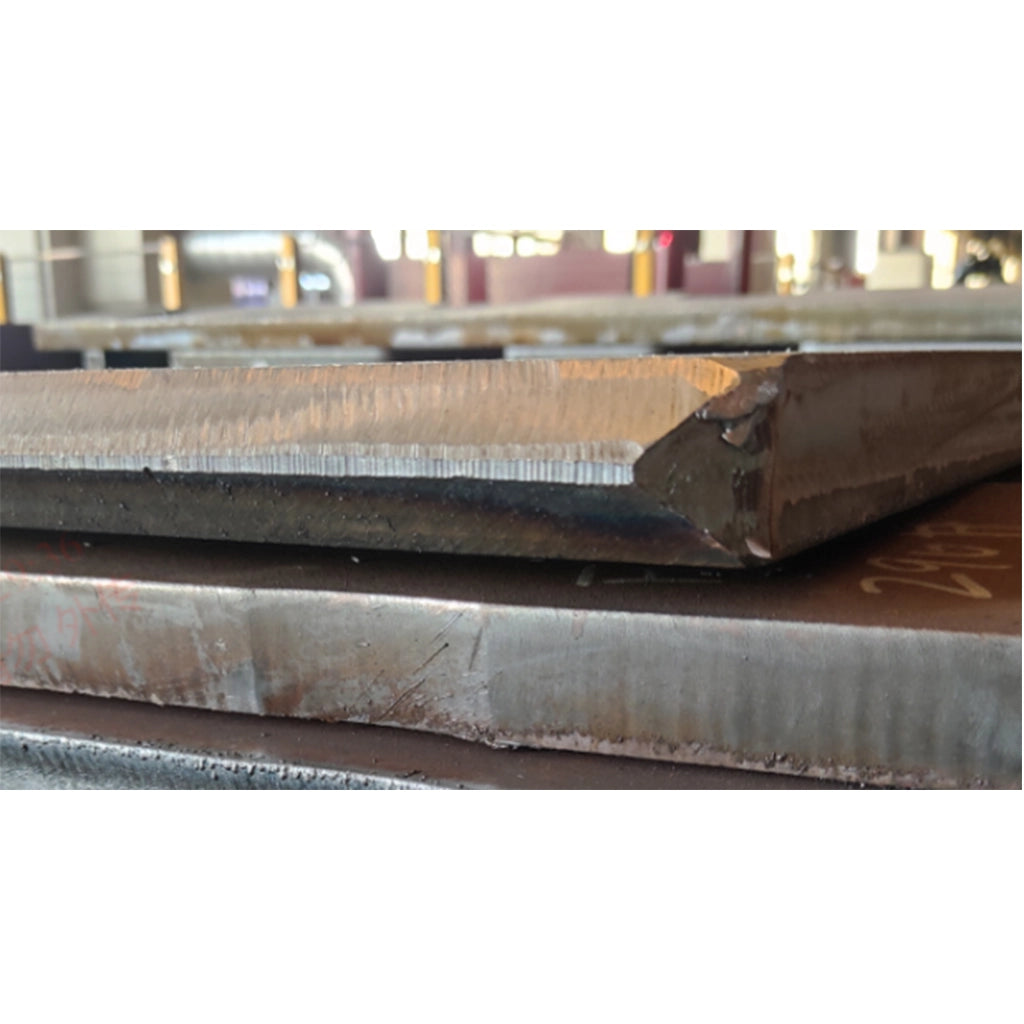

Descripción de la imagen: Corte único y borde común

Efecto Real: En comparación con el biselado de un solo paso, el biselado secundario puede reducir significativamente el área de desperdicio, aumentando la utilización del material en un 5%–10%, lo cual es especialmente significativo para la producción de placas gruesas de gran formato.

2. Ajuste de Proceso Más Fácil

Tomando como ejemplo el procesamiento de un bisel tipo K en una placa de acero al carbono de 30mm (ambos ángulos de bisel superior e inferior son 45°, alturas de 10mm, cara raíz 10mm):

Biselado de Un Solo Paso: El espesor real de corte del bisel alcanza los 42.4mm, requiriendo alta energía de corte; la escoria es escoria dura, difícil de limpiar.

Biselado Secundario: Solo necesita cortar un espesor de 14.1mm, el requerimiento de energía de corte se reduce en dos tercios; la escoria es escoria blanda, más fácil de manejar.

Diferencia en el Efecto: El biselado secundario tiene una velocidad de corte más rápida, una zona afectada por el calor más pequeña, una calidad de superficie de corte significativamente mejorada y una mejor consistencia en la soldadura posterior.

3. Mayor Capacidad de Procesamiento

La capacidad de procesamiento del biselado tradicional de un solo paso está limitada por la potencia del láser, mientras que el biselado secundario supera este cuello de botella optimizando la descomposición del proceso:

|

|

12kw |

20kw |

30kw |

40kw |

60kw |

|||

|

Grosor máximo de corte (corte recto) |

35mm |

60mm |

75mm |

100mm |

110mm |

|||

|

Grosor máximo de corte (bisel a 45°) |

<30mm |

40mm |

55mm |

70mm |

80mm |

|||

|

Procesamiento de bisel secundario |

12kw |

20kw |

30kw |

40kw |

||||

Avance en bisel secundario: Ya no limitado por el umbral de grosor de bisel de un solo paso, permite el procesamiento de bisel superior en Y a 45° en acero al carbono de 100mm con un láser de 40kW, con cara raíz consistente y superficie de corte plana, reduciendo significativamente el requerimiento de potencia de la máquina. Esto significa que las empresas pueden completar el procesamiento de biseles en placas gruesas sin perseguir ciegamente láseres de ultra alta potencia, reduciendo los costos de inversión.

4. Mejora integral en velocidad y precisión

Velocidad de posicionamiento: Las estaciones de trabajo robóticas tradicionales dependen del escaneo de línea única o la enseñanza manual, lo que es lento; la solución de BOCHU utiliza escaneo láser de líneas cruzadas, con una velocidad de posicionamiento de hasta 18m/min.

Precisión de Posicionamiento: Los métodos tradicionales carecen de compensación confiable, la precisión fluctúa; la solución de BOCHU puede controlar la precisión en ≤0.3mm.

Velocidad de Corte: El biselado secundario por llama/plasma es lento; el biselado secundario láser tiene una velocidad aproximadamente el doble que el plasma.

Precisión de Corte: El error en llama/plasma es generalmente >2mm, mientras que la solución de BOCHU puede controlarlo dentro de ±1mm.

5. Ventajas de Costo y Flexibilidad

Costo Operativo: El corte por llama/plasma depende del consumo de gas, lo que genera altos costos a largo plazo; el biselado secundario láser no tiene dependencia de consumibles, ofreciendo un ahorro significativo de energía y reducción de costos.

Producción Flexible: El área de procesamiento puede ajustarse de forma flexible, permitiendo un procesamiento eficiente desde piezas pequeñas en múltiples filas hasta piezas grandes individuales.

Utilización de Restos: Combinado con el sistema Sky Eye y el escáner BCW400F-E, las piezas pueden posicionarse y procesarse incluso cuando se colocan arbitrariamente, mejorando enormemente las tasas de recuperación de restos.

Conclusión

Instalando Bisel Secundario, Sistema Sky Eye, y Escáner en una máquina de corte láser no es solo una mejora de los procesos tradicionales; es un paso crucial para la fabricación hacia una producción inteligente y de precisión.

- El Bisel Secundario resuelve el problema de "bordes cortados que no cumplen con los estándares".

- El Sistema Sky Eye asegura "monitoreo en tiempo real y corrección de errores durante el procesamiento".

- El Escáner hace que el "posicionamiento de piezas complejas y la utilización de restos" sea simple y eficiente.

La combinación de los tres construye una solución de ciclo cerrado de proceso completo que cubre Posicionamiento - Monitoreo - Optimización, ayudando a las empresas a reducir costos, mejorar la calidad y mantener una posición líder en la feroz competencia del mercado.

Preguntas frecuentes

Q1: ¿Qué es el bisel secundario? ¿En qué se diferencia del primer corte?

A1: El primer corte logra principalmente la conformación básica de la placa, mientras que el bisel secundario es el mecanizado fino del borde cortado. Puede corregir defectos generados por el primer corte (como escoria, rebabas, desviación de perpendicularidad) y mecanizar formas de bisel que cumplan con los requisitos del proceso de soldadura.

P2: ¿Por qué es especialmente necesario el bisel secundario para el procesamiento de placas gruesas?

A2: Cuando el espesor de la placa es ≥10 mm, la energía láser tiende a atenuarse durante la penetración, lo que conduce a un corte incompleto en la parte inferior. Si solo se depende de aumentar la potencia en el primer corte, fácilmente causa deformación térmica. El bisel secundario puede realizar un corte dedicado de desbaste trasero dirigido a la parte inferior, asegurando un corte completo y precisión dimensional general.

P3: ¿Qué tipos de biseles puede procesar el bisel secundario?

A3: El bisel secundario soporta varios tipos de biseles, incluyendo ranura en V, ranura en U, ranura en Y y biseles de doble cara, típicamente dentro de un rango de ángulo de 30°–60°. Estos biseles pueden cumplir directamente con los requisitos del proceso de soldadura, evitando lijados manuales adicionales.

P4: ¿Cómo ayuda el bisel secundario a la calidad de la soldadura?

A4: Al mecanizar biseles estandarizados, la brecha de soldadura se vuelve más uniforme y la profundidad de soldadura más estable, reduciendo así riesgos como falta de fusión y penetración incompleta. Es adecuado no solo para soldadura manual sino que también se adapta perfectamente a robots de soldadura automatizados, mejorando significativamente la eficiencia y la resistencia de la soldadura.

P5: ¿El bisel secundario afecta la eficiencia del procesamiento?

A5: Por el contrario, el bisel secundario reduce el retrabajo manual y el lijado, disminuye la tasa de desperdicio (de aproximadamente 5% a menos del 1%). Combinado con el escáner y el sistema Sky Eye, puede aumentar la eficiencia general del procesamiento en un 20%–30%, haciéndolo muy adecuado para la producción flexible.

P6: ¿Para qué industrias es adecuado el bisel secundario?

A6: Los escenarios típicos de aplicación incluyen: procesamiento de piezas soldadas para estructuras de acero, tuberías, barcos, etc.; fabricación de componentes de alta precisión para automóviles, aeroespacial, etc.; escenarios de procesamiento de placas gruesas; reutilización de restos y modos de producción flexibles con alta variedad y bajo volumen.

P7: ¿Cuál es la relación entre el bisel secundario, el "sistema Sky Eye" y el "escáner"?

A7: Los tres se usan a menudo juntos: el escáner es responsable del posicionamiento preciso en las primeras etapas; el sistema Sky Eye se encarga del monitoreo en tiempo real y la corrección de errores en el proceso medio; el bisel secundario es responsable de la optimización de precisión en la etapa final. Forman un bucle cerrado de proceso completo, permitiendo una producción de corte de mayor calidad y más eficiente.